Advanced Technology

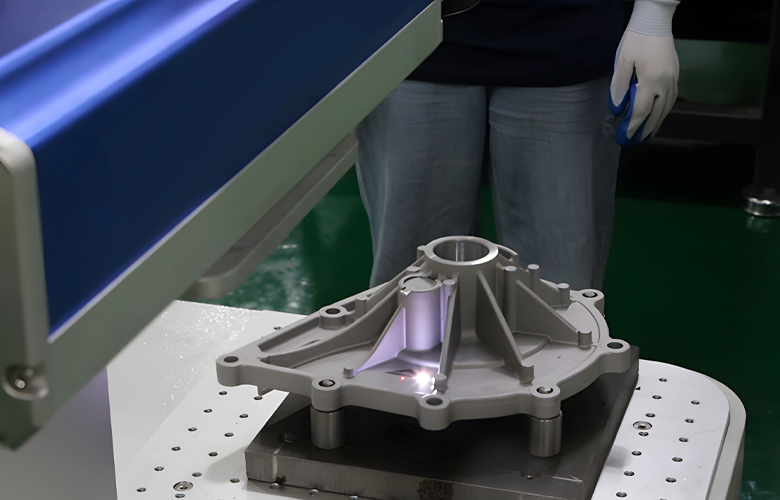

JINGJIE has a complete production workshop and adopts precise manufacturing technology to ensure that every component meets extremely high precision requirements. This not only improves the separation efficiency, but also extends the service life of the product. The company has introduced an automated production line to realize the automation and intelligence of the production process, greatly improving production efficiency and product quality stability. In addition, a large number of environmentally friendly materials such as stainless steel and aluminum alloy are used in the production process. These materials are not only corrosion-resistant, but also easy to recycle, reducing the impact on the environment.